He momo para o te whare te karāhe para, ehara i te mea ka pā kino, ka whakararuraru hoki i te mahi a te tangata me te oranga, engari ka pā kino anō hoki ki te taiao, ka nohoia he whenua utu nui, ā, ka piki ake te taumahatanga ki te taiao. E kiia ana e 3.2 miriona tana o ngā karāhe para e whakaputaina ana e Haina i ia tau, e 2% pea te nui o ngā para totoka o te tāone. Nā te kaha o te motu whānui me te whakapainga o ngā paerewa oranga o te tangata, kua piki ake hoki te nui o ngā karāhe para. Mō te hangarua me te whakamahinga o ngā karāhe para, kua tutuki i ētahi whenua whakawhanake i te United Kingdom me te United States ngā hua whakamiharo. Kua angitu ngā whenua o Ūropi me Amerika ki te whakamahi i ngā karāhe para i roto i ngā kaupapa hanga, he huarahi whai hua tēnei ki te kai i te nui o ngā karāhe para. Nā te mea kāore e hiahiatia kia whakarōpūhia ngā momo karāhe para katoa, kāore he hiahia mō te tae. Hei tauira, ka tukatukahia ngā karāhe para hei rauemi whakapaipai whare i roto i a Mosaic. Hei kaihanga mira karāhe para, ka whakaratohia e te mira karāhe para i hangaia e HCM Machinery he taputapu pai hei āwhina i te hangarua o ngā karāhe para. I tēnei rā, ka whakaatuhia e mātou te tukanga whakaputa o ngā karāhe para hangarua karāhe Mosaic.

1. Te Whakamahinga Pai o te Toka Phosphate: Ko te mahi whakapainga pai o te toka Phosphate te taahiraa tuatahi i roto i te tukatuka i te toka Phosphate, e whai ana ki te wehe i ngā kohuke whai hua mai i ngā poke o te toka Phosphate mā ngā tikanga ā-tinana me te matū. Ko ngā tikanga whakapainga noa ko te wehenga ā-papatipu, te whakapūmau me te wehenga aukume. Ka whakamahia e te wehenga ā-papatipu te rerekētanga mātotoru o ngā kohuke i roto i te konganuku hei wehenga, ka whakamahia e te whakapūmau te rerekētanga pūmau o ngā kohuke i roto i te konganuku hei wehenga, ā, ka whakamahia e te wehenga aukume te rerekētanga aukume o ngā kohuke i roto i te konganuku hei wehenga.

2. Te kuru me te huri i te toka phosphate: i muri i te whakapainga, me kuru me te tukatuka i te toka phosphate, kia pai ake ai te tuku i ngā kohuke whai hua i roto i te konganuku. Ko te kuru he mea whakamahi i te kuru kauae, te kuru kōne me ētahi atu taputapu hei wawahi i te toka phosphate kia rite ki te rahi o te matūriki. Ko te huri he whakamahi i te mīhini hanga me te tukatuka paura phosphate nui hei huri i te konganuku kuru, kia tutuki ai ngā whakaritenga kikokore e hiahiatia ana.

3. Te Whakarewa i te toka phosphate: Ko te whakarewa he taahiraa matua i roto i te tukatuka i te toka phosphate, e taea ai te whakarewa i ngā kai whai hua pēnei i te phosphate mai i te konganuku. Ko ngā tikanga whakarewa e whakamahia whānuitia ana ko te whakarewa waikawa, te whakarewa kawakore me te whakarewa waikura. Ka whakamahia e te whakarewa waikawa he otinga waikawa hei whakarewa i te phosphate, ka whakamahia e te whakarewa kawakore he otinga kawakore hei whakarewa i te phosphate, ā, ka whakamahia e te whakarewa waikura he matū waikura hei whakarewa i te phosphate.

4. Te ua me te tātari i ngā konganuku phosphate: Whai muri i te tangohanga, me whakapūpū te otinga o ngā wāhanga whai hua pēnei i te phosphate me te tātari hei wehe i ngā hua phosphate totoka. Ko te ua te whakamahinga o te matū whakapūpū hei huri i te wāhanga phosphate o te otinga hei pūpūpū totoka, ā, ko te tātari te wehenga o te paru mai i te otinga mā te taputapu tātari.

5. Te whakamaroke me te whakapūkara i te toka phosphate: I muri i te tātaritanga o te paru, me whakamaroke me te whakapūkara kia puta ai te hua phosphate kua oti. Ko te whakamaroke he whakamahinga o ngā taputapu whakamaroke hei mimiti i te wai i roto i te paru, ā, ko te whakapūkara ko te whakamaroke i te paru i te whakapūkara pāmahana teitei, kia puta ai he matūriki phosphate matotoru.

6. Te tukatuka i ngā para o te phosphate: ka puta he nui o ngā para i roto i te tukanga tukatuka phosphate, kei roto i ngā para he kohuke me ngā poke kāore i tangohia. Hei whakaiti i te parahanga taiao me te moumou rauemi, me tukatuka ngā para. Ko ngā tikanga tukatuka para noa ko te whakarārangi i ngā para, te hangarua i ngā para me te whakamahi whānui i ngā para.

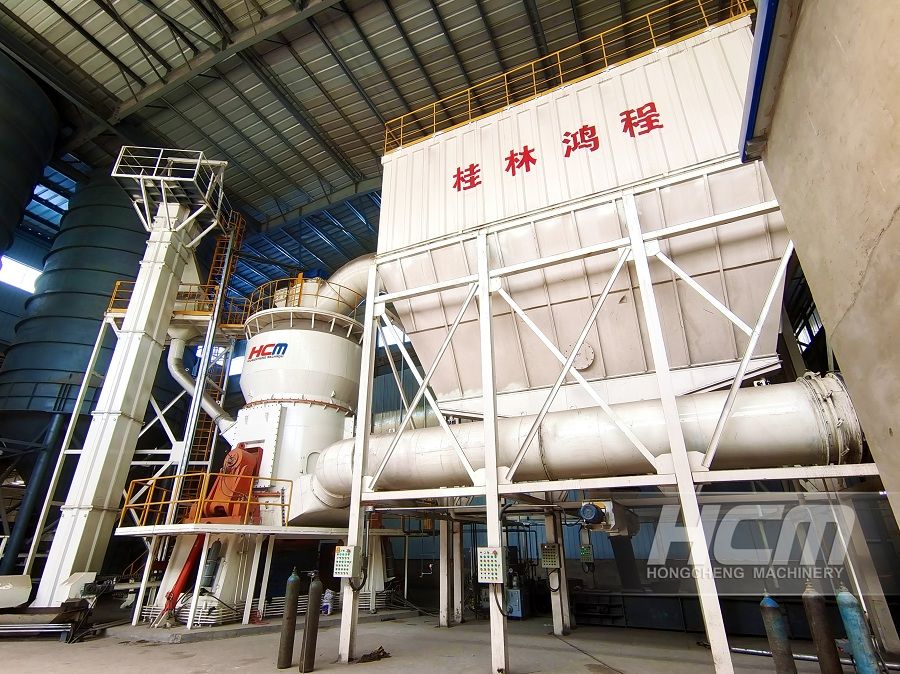

Te tukanga whakaputa o te hangarua karāhe para i roto i te Mosaic karāhe: ko te tikanga sintering me te tikanga rewa te tikanga e whakamahia whānuitia ana, ā, he rite tonu te tikanga whakaputa o te tikanga sintering me te Mosaic uku. Ko te tukanga whakaputa matua ko te huri i te karāhe para mā te mira karāhe para kia tutuki ai ngā whakaritenga o te pai o te paura karāhe, kātahi ka tāpirihia he nui o te kaitapiri (he kēne kore-waro, he kēne waro rānei) me te kaitapiri tae, te kaitapiri tango tae rānei, me te whakaranu hei whakaranu kia rite te hanganga. Ka pēhia te ranunga ki ngā āhua āhuahanga rerekē mā te tikanga pēhi maroke, ā, ka tukuna te tinana maroke ki te oumu roera, ki te oumu pereti pana me te oumu kauhanga me te pāmahana o te 800-900 nekehanga Celsius mō te sintering. I te nuinga o te wā, ka noho ki te rohe pāmahana sintering mō te 1.5-2.5 hāora. Ina whakamataohia ngā hua mai i te oumu mō te tirotiro, te whakatakotoranga, te whakamaroke, te tirotiro, te tākai, te rokiroki, te wheketere rānei, ka hangarua ngā hua kore tohu. Ko te tikanga whakarewa e ahu mai ana i te karāhe para (ko te tokomaha o te tangata he 25-60%) hei rauemi mata matua, ka tāpirihia he nui o te onepu silica, te feldspar, te kōhatu, te pungarehu houra me te kaihoko whakaehu, ka tāpirihia te kaihoko tae mā te tikanga huri karāhe para kia rite te paura, kātahi ka rewa ki roto i te oumu rewa pāmahana teitei (ko te pāmahana rewa he 1400-1500) kia rewa kia rite te wai karāhe. Ka rere te wai karāhe ki roto i te maramataka, ka pēhia ki roto i tētahi poraka karāhe o tētahi rahi me tētahi āhua, ka tukuna ki te oumu whakamahana. Ka taea te penapena, te tuku rānei i ngā hua whakamahana i muri i te tirotiro, te whakanoho me te takai.

Ko te hangarua para karāhe Ko ngā mosaic karāhe e hangai ana ki te huri i ngā para karāhe hei paura karāhe. Ko te mira karāhe para he taputapu whakaputa mō te tukatuka i te paura karāhe. Ko te mira karāhe para i hangaia eMīhini HCM has HC, HCQ and other models, which can process 80-400 mesh glass powder with large output, low energy consumption, small equipment area and simple technology. If you have waste glass recycling needs, welcome to call us to learn more about waste glass mill equipment:hcmkt@hcmilling.com

Wā tuku: Hanuere-08-2024